Cleaning Aluminium from Bits

This guide is taken from the works of Graham Bland

Why do you need to do this?

When cutting aluminium, which is a soft metal with a relatively low melting point, a process called friction welding can occur between the surface of the bit, which leaves some aluminium welded to the cutting surfaces of the bit or stuck in the flutes. This dulls the bit and reduces its efficiency. Of course, if you get your speed, depth of cut and federate correct for the bit, this is less likely to occur.

This only occurs when milling or engraving Aluminium, other soft metals such as Copper and Brass do not tend to weld themselves to the bit which is good as this cleaning process only works on Aluminium deposits.

If your bit looks clean and has no aluminium welded to it, then you don’t need to do this!

There can be other factors such as the bit becoming clogged due to reasons such as the idiot mistake of cutting through the double-sided tape holding the stock down. You can pick off any tape, but you cannot scrape any aluminium welded to the bit off. If you try firstly, you won’t succeed and secondly, you will damage the bit and coating.

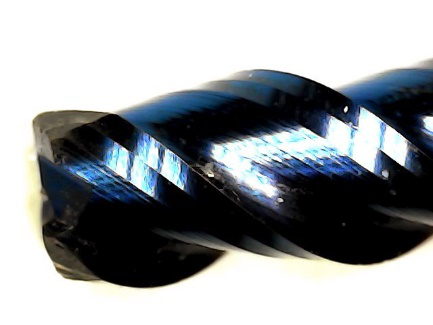

So if after cutting aluminium you have a bit that looks like this, don’t just bin it!

How to Clean Aluminium from Bits

Sodium Hydroxide, known also as Caustic Soda and in some countries Lye, in a strong solution dissolves Aluminium. The really neat thing is that it does not affect other metals such as Carbide or HSS or the coatings used on milling bits.

Noted: The concentration of the solution should be approximately 6 parts cold or lukewarm, (Not hot. The simple act of dissolving the powder will give off heat.), water to one part of powder measured by volume. Please use a pair of good rubber gloves and eye protection when making or handling the solution, and also do it outside.

Cleanning Steps

Step 1: Take a small glass container.

Step 2: Add the water, you don’t need a lot of the solution, just enough to cover any affected parts at the end of the bit.

Step 3: Add the Sodium Hydroxide powder a little at a time while stirring, with something that does not contain Aluminium, until dissolved. DO NOT add the water to the powder. Basic chemistry, if you do, you will start off with an Ultra strong solution which can fizz, spit and give off a lot of heat.

Step 4: Place the end of the bit in the solution and leave for a while (10-15 minutes) occasionally stirring it. It may fizz a little as the aluminium is dissolved and get a little warmer.

Step 5: Remove the bit from the solution and if there appears to still be aluminium on the bit, put it back in and leave it for a while longer.

Step 6: When all the aluminium has disappeared, rinse the bit thoroughly in running water and pat dry.

Step 7: Dispose of the remaining solution by thoroughly diluting it with running water and letting it run down a drain. It is safe to dispose of down the drain, another use of Sodium hydroxide is in drain cleaners. Then rinse out and then wash the container. Rinse and wash thoroughly or dispose of anything the solution has been in contact with, including the rubber gloves.

Completing all the above steps, the bit should look like this. Believe it or not, this is the same SainSmart SN07A 3 flute aluminium cutting bits as shown in the previous pictures.

All traces of aluminium have been removed, cutting edges cleaned and all the flutes cleared, plus the bit coating is completely intact. (The seemingly uncoated parts are just shadows)

Graham have tested this process on SainSmart Uncoated HSS, SainSmart Nano Blue Coat and SainSmart Chromatic coated bits, all of which came out totally unscathed.