Genmitsu MX3 Z-Probe Setup & Operation

Mach3 Software Setup

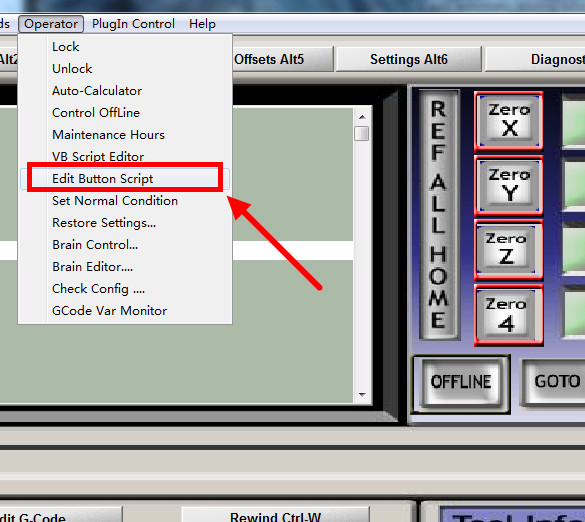

- With Mach3 open, click the Operator tab and from the drop down menu you will want to select Edit Button Script.

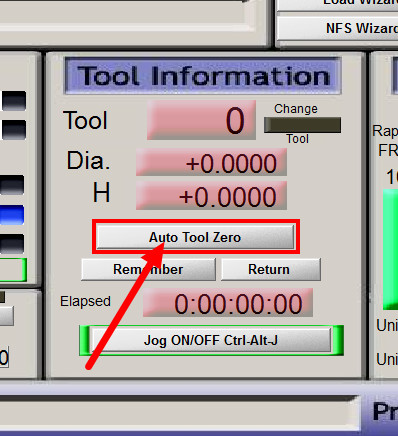

- Buttons that you are able to edit will, at this point, start flashing, and you will want to select the Auto Tool Zero button shown below:

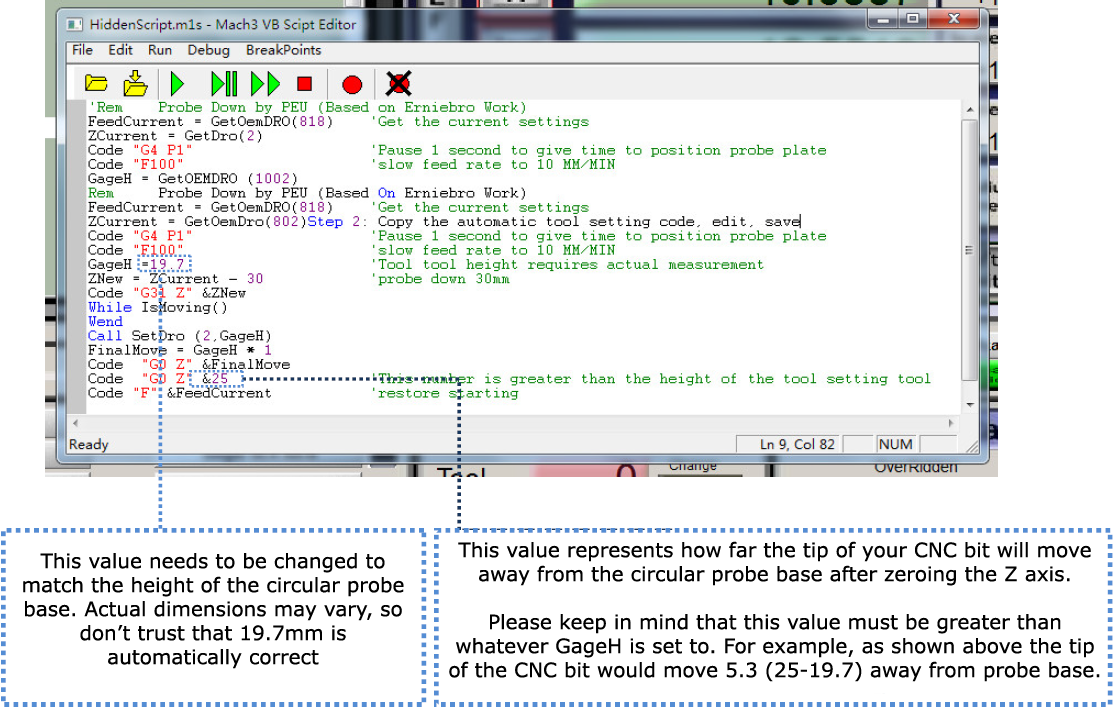

- A blank script editor pate will appear. Copy and paste the contents below into the script editor, but Do Not Save & Close until going through the next step.

'Rem Probe Down by PEU (Based on Erniebro Work)

FeedCurrent = GetOemDRO(818) 'Get the current settings

ZCurrent = GetDro(2)

Code "G4 P1" 'Pause 1 second to give time to position probe plate

Code "F100" 'slow feed rate to 10 MM/MIN

GageH = GetOEMDRO (1002)

Rem Probe Down by PEU (Based On Erniebro Work)

FeedCurrent = GetOemDRO(818) 'Get the current settings

ZCurrent = GetOemDro(802)

Code "G4 P1" 'Pause 1 second to give time to position probe plate

Code "F100" 'slow feed rate to 10 MM/MIN

GageH =19.7 'Tool tool height requires actual measurement

ZNew = ZCurrent - 30 'probe down 30mm

Code "G31 Z" &ZNew

While IsMoving()

Wend

Call SetDro (2,GageH)

FinalMove = GageH * 1

Code "G0 Z" &FinalMove

Code "G0 Z" &25 'This number is greater than the height of the tool setting tool

Code "F" &FeedCurrent 'restore starting

- Edit the two lines shown below, based on the below instructions. Once you have done so, save and exit the script editor.

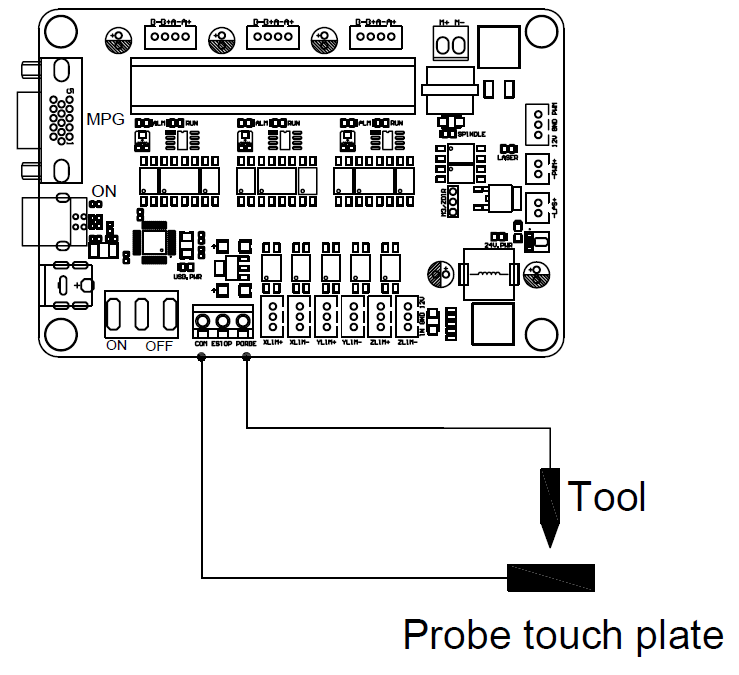

- Connect the Z-Probe Tool as shown below:

Operation

- Attach the Alligator Clip connected to the white wire, and firmly attach it to the bit/end mill that you are planning to engrave with.

- Plave your stock material on your CNC bed. Once secured and in place. put the circular probe base with the metal side up on top of your stop material.

- Using Mach 3, jog your CNC so the spindle is over your stock material and probe base.

- Click the Auto Zero Tool button.